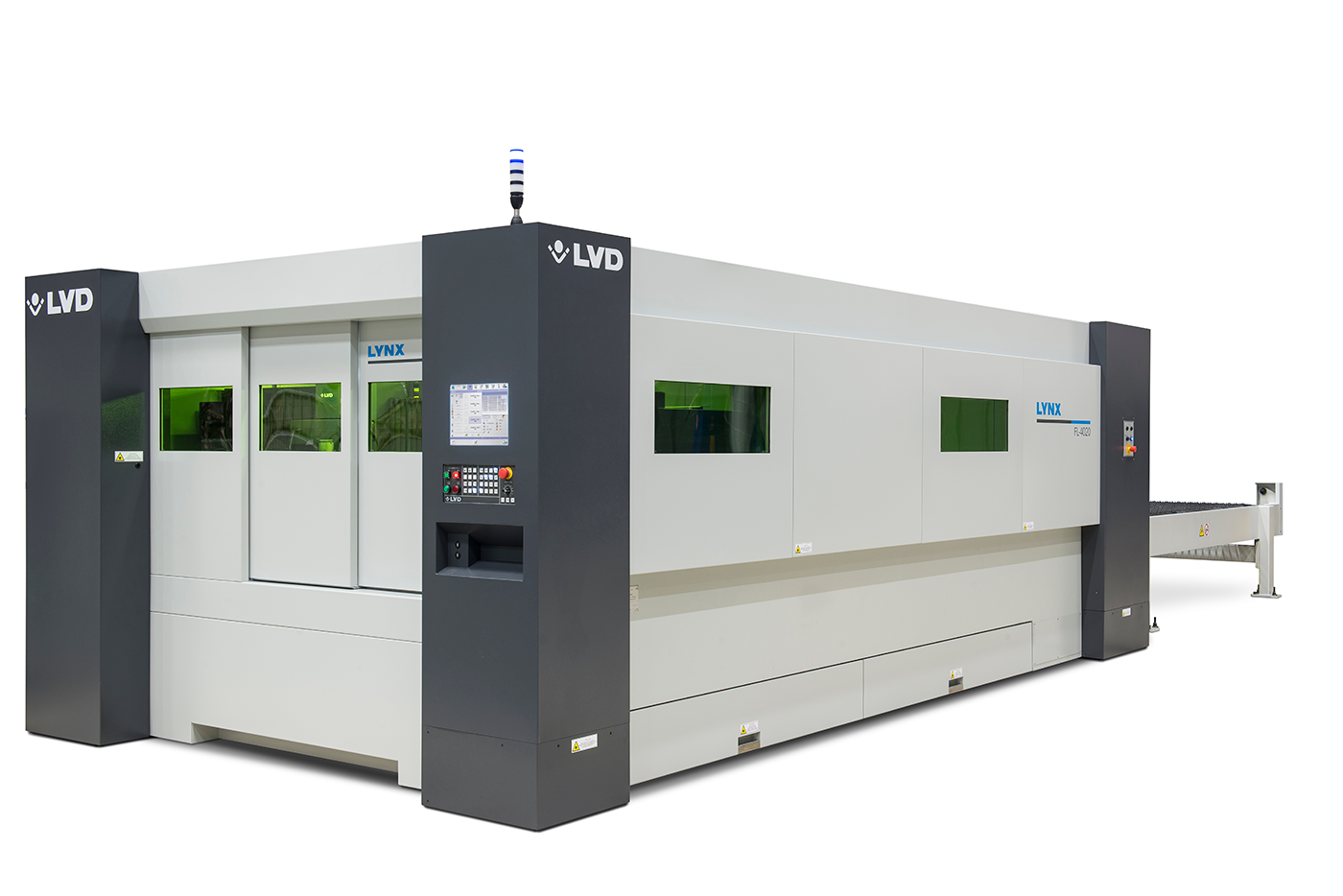

LVD Company nv expands its fiber laser cutting systems product line with the introduction of the Lynx FL, a cost efficient fiber laser cutting system debuting at CIMT, Beijing, April 20th – 25th, Stand W2 – 253.

Engineered For Cost Efficient Laser Processing

Lynx offers users the ability to enter the world of fiber laser cutting with the flexibility to process a wide variety of material types and thicknesses all within a modest and cost effective budget.

Versatile Material Capabilities

Powered by a high efficiency IPG (2 kW) fiber laser source, Lynx provides dynamic, accurate thin sheet processing of traditional sheet metal materials such as mild steel, stainless steel and aluminium with the added versatility to efficiently process metals such as copper and brass. Increased beam absorption of the 1µm wave length laser beam by the material provides processing speeds up to three times faster than CO2 laser sources in thin sheet metal.

Automated Shuttle Change System

A compact design, Lynx maximizes uptime with an integrated shuttle table system that allows one table to be loaded while the machine is cutting on the other table. Table change time is only 35 seconds.

Integrated Control and Drive System

Lynx features an integrated Siemens IU CNC control and drive package guaranteeing the highest accuracy and repeatability even at high speeds.

Cutting Head

The new Precitec “Light-Cutter” guarantees high cutting speed with excellent cutting quality. It incorporates an easy and fast protective glass cartridge change, temperature and constant distance control and a crash-protection system.

Hydraulic shears play a crucial role in modern metal fabrication, providing reliable, high-powered cutting solutions for a wide range of industrial applications. These machines are designed to deliver clean, precise cuts through sheet metal and are essential in workshops and manufacturing environments where efficiency and repeatability matter. If you’re asking, “What is a hydraulic shear?” … Understanding Hydraulic Shears and Their Role in Sheet Metal Cutting

Hydraulic press brakes are a cornerstone of sheet metal fabrication, enabling precise bending for parts in industries ranging from automotive to aerospace. By harnessing hydraulic pressure, these machines apply consistent force to shape metal into channels, angles, and other complex forms. Below, we’ll explore the basic working principle behind hydraulic press brakes, break down their … The Mechanics Behind Hydraulic Press Brakes Explained

The Role of Nitrogen Generators in Industrial Processes Nitrogen gas (N₂) is indispensable across many sectors—ranging from food packaging to chemical processing, and especially in metal industries for laser cutting and heat treatment. Rather than relying on bottled nitrogen cylinders or frequent tank deliveries, an on-site nitrogen generator allows companies to produce high-purity nitrogen directly … How Nitrogen Generators Work: A Detailed Overview