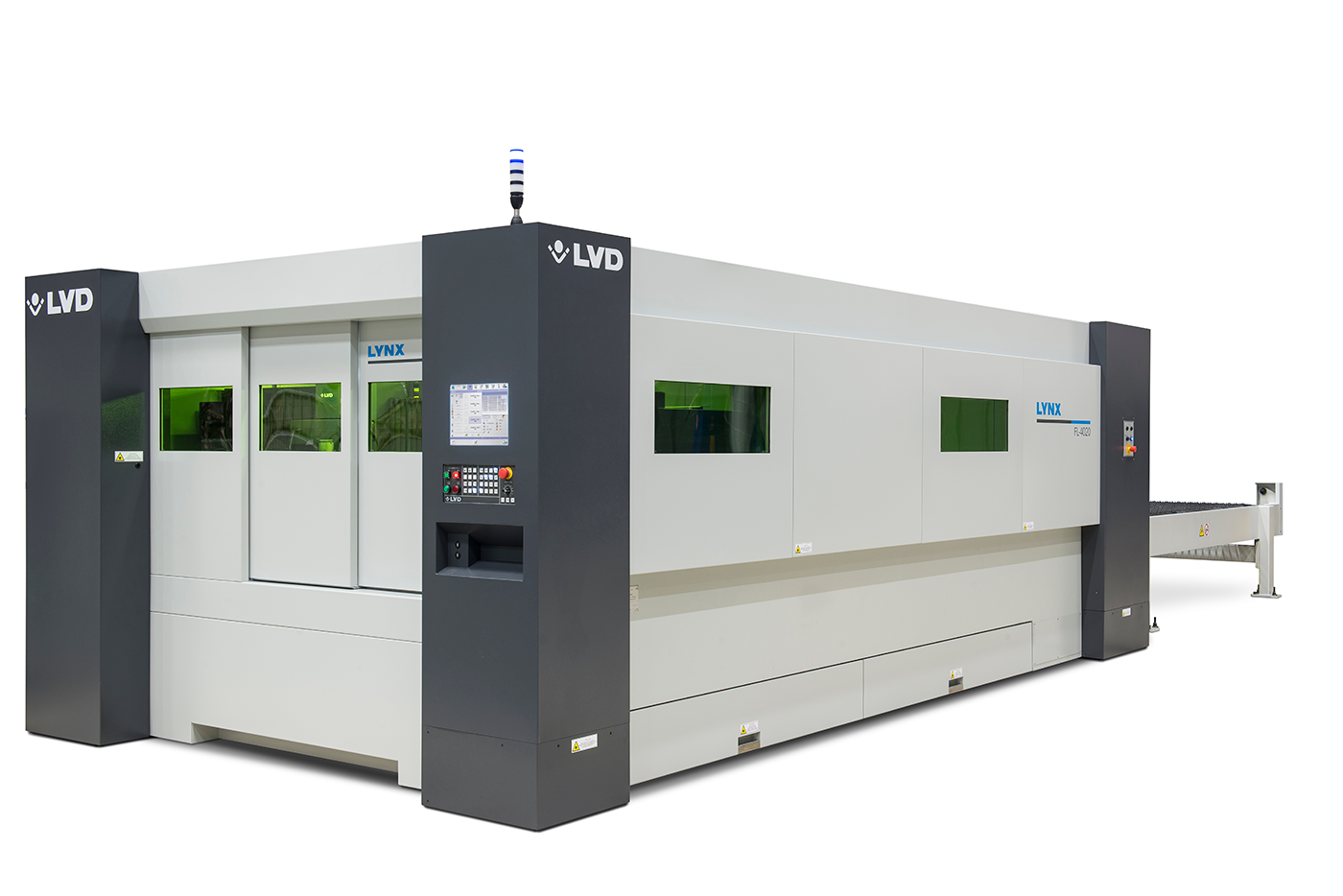

LVD Company nv expands its fiber laser cutting systems product line with the introduction of the Lynx FL, a cost efficient fiber laser cutting system debuting at CIMT, Beijing, April 20th – 25th, Stand W2 – 253.

Engineered For Cost Efficient Laser Processing

Lynx offers users the ability to enter the world of fiber laser cutting with the flexibility to process a wide variety of material types and thicknesses all within a modest and cost effective budget.

Versatile Material Capabilities

Powered by a high efficiency IPG (2 kW) fiber laser source, Lynx provides dynamic, accurate thin sheet processing of traditional sheet metal materials such as mild steel, stainless steel and aluminium with the added versatility to efficiently process metals such as copper and brass. Increased beam absorption of the 1µm wave length laser beam by the material provides processing speeds up to three times faster than CO2 laser sources in thin sheet metal.

Automated Shuttle Change System

A compact design, Lynx maximizes uptime with an integrated shuttle table system that allows one table to be loaded while the machine is cutting on the other table. Table change time is only 35 seconds.

Integrated Control and Drive System

Lynx features an integrated Siemens IU CNC control and drive package guaranteeing the highest accuracy and repeatability even at high speeds.

Cutting Head

The new Precitec “Light-Cutter” guarantees high cutting speed with excellent cutting quality. It incorporates an easy and fast protective glass cartridge change, temperature and constant distance control and a crash-protection system.

Introduction Picking new machine tools can feel a bit like choosing the engine for a race car. The frame, tyres, and paint all matter, but the engine decides how fast and how reliably the car runs. In the same way, the machine tools inside a workshop or production line decide how much work gets out … How To Choose The Right Machine Tools For Your Workshop Or Production Line

Nitrogen generation refers to the process of separating nitrogen from atmospheric air, which naturally contains about 78% nitrogen. For decades, Australian manufacturers relied on traditional supply methods like gas cylinders and bulk liquid deliveries. However, the industrial landscape has shifted dramatically toward on-site nitrogen generation systems. This transformation particularly benefits Australian sheet metal manufacturing companies, … Methods of Generating Nitrogen for Industrial Applications

A press brake stands as one of the most powerful tools in metal fabrication, designed specifically for bending sheet and plate metal into precise shapes and angles. Learning how to use a press brake effectively opens doors to countless fabrication possibilities across automotive, aerospace, construction, and electronics industries. The machine harnesses the natural ductility of … A Practical Guide to Operating a Press Brake